Owning a pool or spa in Santa Clarita can turn long, hot afternoons into a staycation. The water cools you off, but the electrical behind that serenity needs to stay cool too. Pumps, lights, heaters, automation, even the little outlet used for your robot vacuum, all of it lives in a wet, conductive environment. That means two priorities rise above everything else: safety and reliability. When those are handled, the rest becomes easy, including the part everyone loves — clear water, quiet equipment, and lights that glow without flicker or buzz.

I work in neighborhoods from Saugus and Newhall to Valencia and Canyon Country, and the pattern is consistent. Most issues trace back to details skipped in the first build or during a remodel. The best work shows up years later when everything still runs, breakers stay quiet, and no one remembers the last nuisance trip. Here is the playbook I use and recommend to any homeowner evaluating a Santa Clarita electrician or an electrical contractor anywhere in Los Angeles County.

Why pool and spa electrical is its own discipline

Electricity does not forgive casual mistakes around water. A GFCI missing on a pool light, a corroded bond at the pump, or a cracked conduit fitting can turn a simple swim into a hazard. Pools and spas demand hardware and methods that handle wet locations, corrosion, UV exposure, vibration, and chemicals like chlorine and salt. The National Electrical Code has an entire article dedicated to pools and similar bodies of water. If your installation does not reflect that specificity, it is not code compliant.

Regulation aside, you also want gear that lasts. Equipment set near a backyard pool sees 100-degree heat in August, chilly nights in winter, and Santa Ana winds that sandblast surfaces. Cheap equipment fails early, and the failures are rarely cute — think leaking housings, stuck relays, or lighting transformers filling with water. That is why a thoughtful installation costs less across the life of the system.

The safety hierarchy that never changes

Electricians who work pools and spas think in layers. Protection stacks so that if one thing goes wrong, another catches it. I run every project, whether new build or upgrade, through the same hierarchy:

- Keep electricity out of the water with proper separation, listing, and wiring methods. Ensure rapid fault detection with GFCI and bonding so a small issue does not become a dangerous one.

That short list guides everything that follows. If a proposal or plan skips one of those, press pause.

Service size, load planning, and where the power comes from

Before trenching, lighting renderings, or panel choices, confirm that your home can actually support the pool or spa you want. A typical single-speed 2 horsepower pool pump draws 10 to 12 amps at 240 volts. Add a 400,000 BTU gas heater with a 120/240-volt control circuit, a salt system at 4 to 8 amps, two LED niches with a 12-volt transformer, and an automation center with relays and Wi-Fi. Spas push loads higher. A 5.5 kW electric spa heater draws around 23 amps at 240 volts. Add a 2-speed pump, blower, lights, and you can easily need a dedicated 50- to 60-amp subpanel near the equipment.

Many older homes in Santa Clarita still have 100-amp services. That is not a deal-breaker, but it requires careful load calculations, often a service upgrade, or shifting usage. An experienced santa clarita electrician will pull a load sheet before promising the moon. When clients ask why a panel upgrade accompanies a pool addition, the honest answer is simple: the math forces it, and the result is a safer, smoother-running home.

GFCI is not optional, and not all GFCI devices are equal

Ground-fault protection saves lives around water. It must protect underwater luminaires, pump motors, heat pumps, and receptacles near the pool. Too often I find old-style pool light circuits on standard breakers. Those days are gone. Use listed GFCI breakers or, when transformer-fed low-voltage lighting is used, a GFCI-protected primary. For multi-speed or variable-speed pumps, match the GFCI type to the drive. Some VFD-based pumps play poorly with cheap GFCI breakers, causing nuisance trips. Brands publish compatibility charts. A good los angeles county electrician checks that chart rather than guessing.

When nuisance trips do happen, methodical testing is key. Megger the pump motor leads. Isolate the light transformer. Check for pinched conductors at the junction box. Resist the urge to swap the breaker and call it fixed. You want to eliminate causes, not mask them.

Bonding is the quiet hero

Bonding ties all metallic parts together so there is no voltage difference between them. The pool shell reinforcing steel, ladders, diving board anchors, metallic fencing within the prescribed distance, pump motor casings, the heater shell, even the metal mounts for equipment, all bond back to an equipotential grid. That is why you see bare copper running through the equipment pad and encircling the pool during construction.

If you are renovating a decades-old pool, probe for the original bond grid. Sometimes it is there but corroded. Sometimes it was never installed to modern standards. I have seen small zaps on a brushed concrete deck caused by a broken bond at a handrail cup. The fix required cutting a clean pocket, reattaching a bond lug with proper hardware, and verifying continuity back to the grid. Cheap? No. Worth it? Yes, every time.

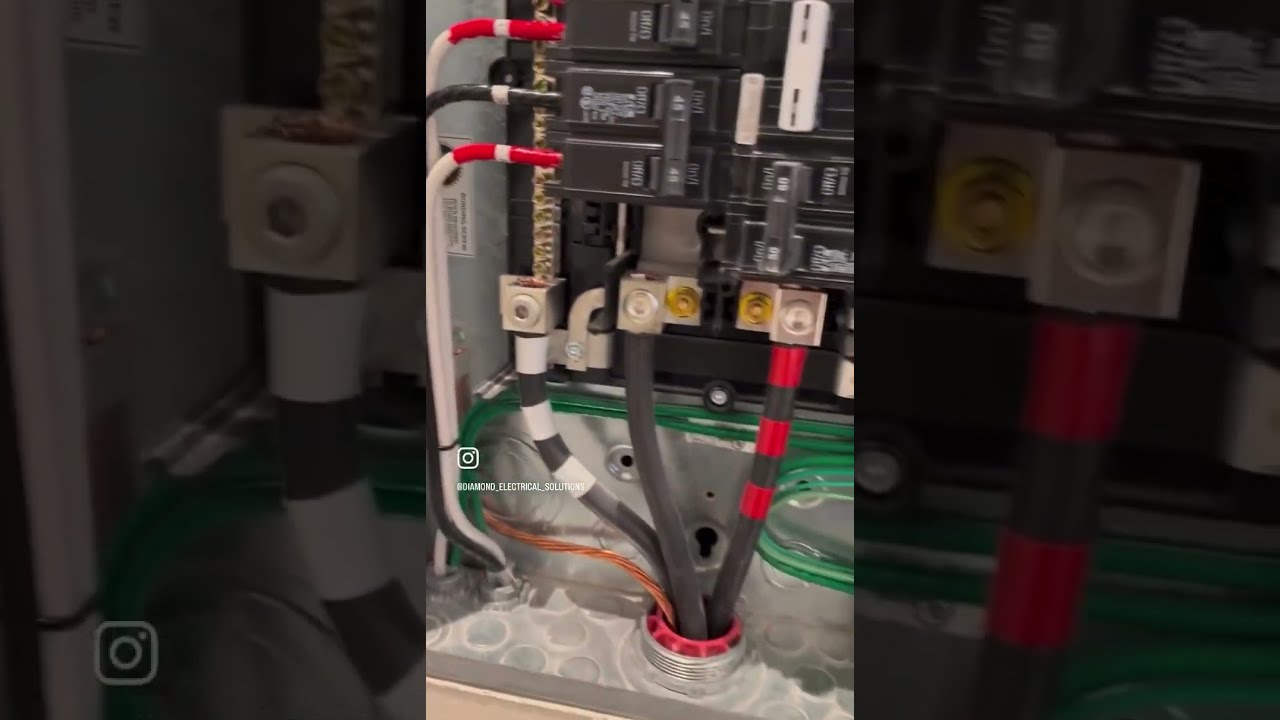

Conduits, boxes, and the unforgiving reality of water

Wet-location wiring methods are non-negotiable. Use proper schedule 40 PVC underground and schedule 80 where exposed. Transitions at stubs and risers should be tight and solvent-welded. I prefer deep, gasketed, NEMA 3R or 4 enclosures on the equipment pad, mounted a couple inches off the wall sleeve to let water drain and air circulate. Avoid back-to-back fittings that trap moisture.

Any underwater light needs a listed niche, a proper junction box or listed luminaire housing set the required distance from the waterline and above the deck, and conduits rising unbroken from the niche to the J-box. No buried splices. No mystery conduits disappearing into soil. If a remodel forces creative routing, get an electrical contractor comfortable with old pool anatomy. It is common to discover conduits filled with silt. That calls for careful vacuuming and pulling new, appropriate wet-rated conductors, not just pushing harder on the fish tape and hoping.

Low-voltage lighting is not a free-for-all

LED pool and spa lighting with 12- or 14-volt transformers improves safety, but it does not eliminate code. The transformer must be listed for pool use and installed a minimum distance from the water line. Mount it where it breathes and stays dry, on a dedicated circuit or a GFCI-protected branch. Separate pool and landscape lighting circuits if possible. A short in a garden light string should not black out the pool, and vice versa.

If you are chasing that magazine look with color-changing LEDs tied to automation, spec brands that talk to your control system natively. Mixing and matching can lead to limited color scenes or erratic syncing. It seems like a small disappointment until the homeowner realizes their expensive controller cannot do the light shows they expected.

Variable-speed pumps, harmonics, and keeping the peace with your GFCI

Variable-speed pumps are standard in Santa Clarita because they slash energy use. A typical pump running at 1,500 RPM may draw around 150 to 300 watts, a fraction of the old 2-speed on high. The catch is the internal drive creates electrical noise. Cheap wiring practices sub panel installation make that noise everyone’s problem. I like to keep the pump circuit isolated, run clean, and keep neutrals tidy at the panel. Use the GFCI breaker recommended by the pump manufacturer. If you have automation, avoid stacking low-voltage control cabling directly on power conductors. That small change prevents phantom commands and glitchy behavior.

A long, exposed conduit run acting as an antenna is a sneaky source of trouble. Keep runs tight, reduce unnecessary junctions, and ground metal enclosures with proper lugs. If you experience trips at random times of day, check for harmonics from nearby large appliances or EV chargers. I have had to re-land shared neutrals and separate circuits at busy panels more than once to quiet down a sensitive pump.

Heaters, heat pumps, and the importance of correct disconnects

Gas pool heaters use modest electrical power but still require clean, GFCI-protected circuits and a service disconnect in sight. Heat pumps draw more and need conductor sizing that respects long runs. Undersized conductors work on cool mornings and then nuisance trip under summer heat when resistance rises. If the equipment pad sits far from the panel, voltage drop becomes part of the calculation. I run 240-volt loads on wire sized to keep voltage drop under 3 percent at full draw. It adds a few dollars in copper and saves hours of headaches later.

Most equipment labels call for a dedicated 60-amp non-fused or fused disconnect, depending on the load. Install it at a height that is reachable without stepping over piping or obstacles. I have seen disconnects mounted behind heaters walled in by gas lines and unions. That is not accessible, and it is not safe.

Automation that earns its keep

Modern automation brings the pool pad onto your phone. Done right, it simplifies life. Done badly, it breeds support tickets. Keep these principles in mind:

- Choose an automation brand aligned with your pump and lights. Native integrations work better than adapters. Provide stable power and good Wi-Fi to the pad. Many systems rely on cloud connections, and weak coverage means delays, retries, or timeouts.

Plan for manual overrides. A labeled toggle for the spa, a clear switch for pool lights, and a good-old-fashioned pump power switch prevent frustration when an app freezes. During commissioning, I walk clients through the physical gear and settings, then show the app last. That ensures they are never stuck waiting on software to enjoy the water.

Outdoor receptacles and working spaces that do not cause stumbles

Pool areas invite corded tools, robotic vacuums, and entertainment gear. Code calls for GFCI-protected receptacles with in-use covers and spacing that avoids running cords across walking paths. Keep outlets a safe distance from the water and at convenient heights. I often add a 20-amp GFCI-protected circuit near the equipment pad for service tools, then distribute a few extra outlets around the yard for landscape needs.

Working clearance at the equipment pad matters more than most people realize. The minimum space around electrical gear is there so a technician can service it without standing in mud, twisted around pipes, with no way out. When planning pad layout, I leave a comfortable service aisle and mount controls at a height where you do not need a step stool.

Corrosion is not a maybe

Salt systems and coastal air both accelerate corrosion. Santa Clarita is not the beach, but saltwater pools put metal on the clock. I specify stainless hardware, nonconductive stand-offs, and sealed enclosures with drip loops on all entries. It is a small collection of habits that together keep boards and breakers clean. If a client uses a salt chlorine generator, I bond the cell correctly and keep sensors and control boards sheltered from spray. A corroded cell union or a seized bonding lug turns simple maintenance into a costly repair.

Remodels and the archaeology of old pools

Remodeling a 1980s or 1990s pool often means discovery. Conduits may be shallow or unglued. Bond wires disappear mid-run. Light niches may be incompatible with modern LEDs without adapters. I set expectations early. We open a box, we test, we document. If we find brittle conductors, we pull new THWN-2 rated wire and test insulation values before landing anything on a breaker. If underground conduits are clogged, we plan a surgical trench rather than forcing wire through a mud-filled pipe.

One client in Valencia bought a home with a spa that kept tripping the GFCI at random. The last owner replaced the breaker twice. We found a cracked splice inside a buried, unsealed junction feeding the spa light. It stayed dry for months, then wicked moisture after heavy irrigation. A proper above-deck J-box, new conductors, and a listed transformer solved it. The repair took half a day. The diagnosis took experience and patience.

Inspections, permits, and being on the same side as the AHJ

Different cities in Los Angeles County interpret pool requirements with local flavor. Santa Clarita inspectors care about bonding terminations, GFCI labeling, and working clearances. County inspectors may look closely at lighting transformers and set-backs. A good los angeles county electrician knows the local authority having jurisdiction, confirms plan requirements, and welcomes the inspection. On remodels, I like to photograph the bond grid and conduit routing before shotcrete or deck pours, then share those images at inspection. It shows intent and makes everyone’s day easier.

Permits matter for one more reason: resale. A documented, permitted pool electrical system spares you grief later when a buyer’s inspector asks hard questions. Real value often shows up when you go to sell.

Maintenance is not glamorous, but it is cheap insurance

After a clean installation, make maintenance simple. Once a year, open enclosures, look for rust blooms, tighten lugs to spec, vacuum dust, and verify GFCI trips. Variable-speed pumps ship with filters that need occasional cleaning. If you have automation, update firmware during the off-season. Confirm that bonding connections remain intact after landscape changes. These are small tasks that extend life and reduce emergency calls when you want to host a weekend swim.

If a breaker starts tripping after a quiet year, do not jump straight to replacement. Something changed. A new landscape light, a mower-damaged conduit stub, a cracked in-use cover after a windstorm, even a smart plug added to the equipment circuit, all can introduce faults. Track changes, test in steps, and you will find the cause faster.

Energy, noise, and neighbor-friendly choices

Santa Clarita nights are still, and equipment noise carries. Mount pumps on proper pads, isolate vibration with rubber feet, and align plumbing to avoid resonant hums. Variable-speed pumps should run at lower RPMs during quiet hours. If you have a heat pump, place it where airflow is unobstructed and noise is buffered by fencing or landscaping.

On energy, a well-programmed variable-speed pump can cut consumption by 50 to 80 percent compared to single-speed. Schedule filtration during off-peak hours if your utility rate plan encourages it. LED lights across the system draw a fraction of old incandescent lamps, and they run cooler and last longer. Practical changes, not just new gadgets, deliver the savings.

When to call a specialist

DIY has limits at the water’s edge. If you see any of the following, bring in a qualified santa clarita electrician who knows pools:

- GFCI trips that do not correlate to motor starts, weather, or obvious faults. Tingling sensations on wet decks, ladders, or handrails, even if faint. Lights that flicker or fail repeatedly, especially after rain or irrigation. Evidence of corrosion inside control boxes or around bonding points. Mystery conduits, unknown splices, or undocumented remodels.

An electrician who works pool systems will arrive with a megohmmeter, a clamp meter, and a methodical approach, not just a spare breaker.

Choosing the right contractor for a backyard you trust

Credentials count, but what you want most is judgment. Ask how they handle bonding on remodels. Listen for specific answers about GFCI types for your pump, transformer selection for lights, and how they route conduits to stay dry. A solid electrical contractor should be comfortable coordinating with your pool builder, plumber, and landscaper, and should defend working clearances, conduit integrity, and equipment protection even when aesthetics push the other way.

Local experience matters. Soil in Santa Clarita can be rocky, and trench depth is not always trivial. UV is brutal on cable jackets and cheap plastic. Wind-driven debris finds its way into every opening. Someone who has repaired systems here knows where to overbuild by a margin.

A short homeowner checklist before you sign off

- Open the equipment panel and read labels. Every circuit should be clear, and the GFCI devices identifiable. Find the bonding connections. You should see a bare copper path tying metal parts together, with secure lugs and no green fuzz. Look for drip loops on all conductors entering enclosures, and in-use covers on outdoor outlets. Test the spa and pool lights, then operate them from the app and from a physical switch. Verify that you have the manuals, breaker schedules, and a quick diagram of the system layout for future reference.

The long view

Great pool and spa electrical work is almost invisible. It does not call attention to itself. The system starts every time, quietly, for years. The only times you think about it are when you want the water a few degrees warmer for a late soak or when your kids ask for purple lights on a Friday night. That quiet background reliability comes from choices made on day one by a careful technician, a conscientious homeowner, and a plan that respects both the code and the backyard you live in.

If you are weighing bids or considering upgrades, ask pointed questions, insist on the right methods, and choose the professional who welcomes those questions. Whether you call a los angeles county electrician from a larger firm or a local santa clarita electrician with a tight crew, the best practices remain the same. Build the layers of safety, protect against water and corrosion, plan the loads, and keep maintenance simple. Do that, and your pool or spa becomes what it should be: a place to relax, not a project to manage.

American Electric Co

26378 Ruether Ave, Santa Clarita, CA 91350

(888) 441-9606

Visit Website

American Electric Co keeps Los Angeles County homes powered, safe, and future-ready. As licensed electricians, we specialize in main panel upgrades, smart panel installations, and dedicated circuits that ensure your electrical system is built to handle today’s demands—and tomorrow’s. Whether it’s upgrading your outdated panel in Malibu, wiring dedicated circuits for high-demand appliances in Pasadena, or installing a smart panel that gives you real-time control in Burbank, our team delivers expertise you can trust (and, yes, the occasional dad-level electrical joke). From standby generator systems that keep the lights on during California outages to precision panel work that prevents overloads and flickering lights, we make sure your home has the backbone it needs. Electrical issues aren’t just inconvenient—they can feel downright scary. That’s why we’re just a call away, bringing clarity, safety, and dependable power to every service call.